| |||||

PEEL-CONNER TELEPHONE WORKS LTD.by Alan Gall and Bob Estreich

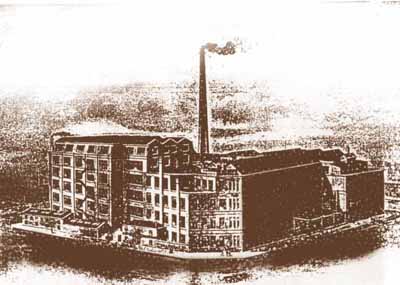

The history of Peel Conner is difficult to untangle, as it was not really an independent telephone manufacturer at all. From 1910 to 1921 it was the telephone manufacturing works of Britain's General Electric Company, and its name was more accidental than deliberate. GEC was founded in 1886 to import and sell electrical goods, including telephones. They were quite successful and in 1888 they opened a factory in Salford (often reported as Manchester because of the close proximity of the two cities). This was known as the "Manchester Works". They had another factory in Salford nicknamed the "Peel Works" because it overlooked Peel Park. Peel Park was named after Sir Robert Peel, the local Member of Parliament and the originator of the British Police Force. Following a fire in the Manchester Works in 1895 (not 1893 as listed in Company histories - the 1895 date is confirmed by newspaper reports) all construction was moved to the Peel Works. M S Conner Around 1909 Merritt Scott Conner entered the picture. Born in Paw Paw, Michigan, around 1874, Conner worked for a time for Bell Canada. In 1906 he received a Canadian patent for an improved telephone signalling system, details of which are now unavailable. He moved to Britain and joined the Peel Works and proceeded to improve the quality of the telephones produced there. Among his British patents are: 1909 An interlocking system for banks of switches that reset all switches once another key was pressed. 1909 A call counter for telephone exchanges 1910 An improved design for the bell receiver, incorporating better magnetic field location and better rigidity of construction. 1910 Further construction improvements to the receiver 1910 A method to quickly coat wire with paint or other preservative 1910 and 1912 A way to feed local power to an extension phone while it is connected to an exchange line, reducing the volume drop. This system allowed a bell to ring when the extension phone was hung up, so the switchboard operator could clear the line and extension. Another signal was sent to the public exchange to allow the operator there to clear the exchange end of the call. 1917 Further improvements to the magnet construction and layout in the telephone receiver 1917 An improvement to the Solid Back transmitter to prevent distortion of the diaphragm during assembly. 1913 An improved two-piece switchhook that reduced the problem of sticking of single-piece switchhooks. 1913 A rotary switch using ball bearings in the switch for the moving contacts. This proved more electrically reliable and less prone to wear than fixed metal wiper-style contacts. 1912 An automatically-resetting indicator for annunciators Many of these were patented in conjunction with other engineers at the Works, and many (such as the rotary switch, the self-resetting switchbank, and the call counter) went on to become standard items of equipment in the telephony industry. These inventions highlight two points - just how inventive Conner was, and also that the industry had now settled down to a level of steady improvement rather than major inventions. There were other inventions, such as the stamping and folding of steel sheet to form the lamp holders for switchboards, rather than assemble each one from brass tube. These were production improvements that would have made the factory more efficient and given them a competitive edge over the older hand-assembly methods. Conner eventually returned to the United States, where the 1930 U.S. Census records him as living in New York State. Peel-Conner Telephone Works Ltd

The new company produced telephones exclusively. The 1910 Annual Report notes "Switchgear, arc lamps, fans and small motors departments have now been moved from Salford to Witton. Peel Works is now entirely devoted to telephone and telegraphic apparatus. The Directors have thought it desirable to carry on these departments as a subsidiary company". The company produced everything from parts to full telephone exchanges. Their

first exchanges were at Glasgow (10,000 lines expandable to 14,400) and Willesden.

Export markets were actively sought. The new company made its first export sale

to Australia in 1911. It sold the PMG Department 8000 lines for new exchanges

in the Adelaide area comprising six exchanges at Central, Prospect, Glenelg,

Brighton, Henley and Woodfield. In the 1912 GEC catalogue the company notes that it "holds the sole right of sale to the trade of the products of the Peel-Conner Telephone Works Ltd." In addition, GEC sold telephones from L M Ericsson (telephones and parts), Alfred Graham (ships phones), Fox-Pearson (fire alarms), Sinclair (insulators) and many others. Peel-Conner was also making Western Electric-pattern telephones and parts for the British Post Office under the BPO's contract-sharing arrangements, designed to support local manufacturers.

Left: This works truck is unusual in that it shows both the GEC and Peel Conner brands. Courtesy Alan Gall

It may be that Peel-Conner never published a catalogue of its own. Its phones are known from GEC catalogues only. There seems to have been some attempt to keep up a pretence of separation of the two companies. The BPO allocated a separate manufacturers code to Peel-Conner (AK) , and GEC listed Peel-Conner telephones under the P-C brand, but both companies used GEC's magnet logo and it is unlikely that the pretence fooled anyone.

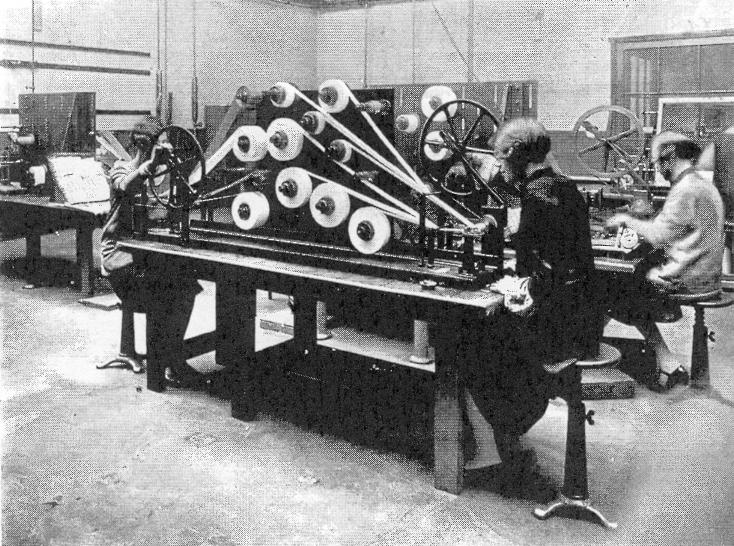

Left: Winding condensers by hand, Peel Conner Works. Photo courtesy Alan Gall

The telephone industry changed after World War 1. Magneto exchanges were being dropped in favour of the more efficient CB exchanges. Increasingly, automatic exchanges were being introduced, something Peel-Conner had not developed into. The British Post Office had standardized on a few designs of telephone and the specialised telephones market was contracting. Bakelite moulding was introduced, and this required redesign of the phones and heavy investment in the chemical equipment and high-pressure presses required for the new medium. This investment was put into the new GEC Coventry works. In 1921 GEC liquidated the Peel-Conner company and moved all its manufacture to the bigger Coventry factory. It continued to use the name Peel Conner Telephone Works for the Coventry factory, but its phones were gradually rebranded GEC. Eventually the name fell into disuse as the GEC conglomerate branched out into many other areas.

| |||||

On 24th December

1910 GEC incorporated the factory as a separate company, employing a thousand

workers. The "Electrical Review" noted that the company had been formed

to adopt an agreement between GEC and Conner to take over the Peel Works' telephone

manufacturing. Conner's importance to the company was acknowledged by his nomination

to the Board of the new company. The other board members were: Directors G Byng

and H Hirst (the founders of GEC), and J Fraser, E G Byng, and the P P Kipping,

the company Secretary. Each held 500 shares. Unfortunately by the incorporation

of the company, Gustav Binswanger (G Byng - he anglicized his name) had died.

On 24th December

1910 GEC incorporated the factory as a separate company, employing a thousand

workers. The "Electrical Review" noted that the company had been formed

to adopt an agreement between GEC and Conner to take over the Peel Works' telephone

manufacturing. Conner's importance to the company was acknowledged by his nomination

to the Board of the new company. The other board members were: Directors G Byng

and H Hirst (the founders of GEC), and J Fraser, E G Byng, and the P P Kipping,

the company Secretary. Each held 500 shares. Unfortunately by the incorporation

of the company, Gustav Binswanger (G Byng - he anglicized his name) had died.