| |||||

Indian Telephone Industries 332 Bakelite TelephonesThese telephones started appearing on the second hand market around a decade ago, and quickly became notorious as copies or fakes of the British 332 telephone. They are neither. Most of them are genuine telephones, manufactured and used in India, using local parts and materials and a design and moulds sourced from Britain, where the 332 phone had become obsolete. They are "genuine" telephones, in the same line as the Irish, Portugese or Australian versions of the 332. There was however a small batch of poor-quality remakes produced using ill-fitting parts, but apparently made from the original moulds. The bad reputation of the Indian phones was caused by unscrupulous or uninformed dealers who sold both the remakes and the ITI phones as British phones, at British prices. Indian Telephone Industries Ltd was established at Bangalore by the Indian Government in 1948 to begin local manufacture of telephones. It has grown over the years and now manufactures a full range of telephones, switchgear and other parts. It boasts six factories, and is a major contributor to India's communications. In the 1950s, however, it needed a telephone to build and it did not yet have the design skills to design and build its own. It imported the 332 telephone parts from ATM in Britain for a couple of years and assembled them locally. Britain had just replaced their 332 telephones with the new 700 series, Bakelite had given way to newer plastics. ATM sold their superseded moulding equipment to ITI, and ITI used this to start production.

The British Post Office 332

The baseplate had a pressed-in dish to allow rails to be fitted for a note tray at the front of the phone. Not all phones were so fitted, and a blanking plate filled the hole at the front on most phones. The note drawer fitting meant that the phone's works had to be mounted on a chassis above the rails. The baseplate will be marked with the manufacturer code and the year of production eg: E 52 over 332 (E for Ericssons) The cord was originally a twisted cotton covered one, color-matched to the telephone. In the course of production it was changed to a rayon-covered anti-twist version of high quality, cotton-wrapped and reinforced wherever it entered the case or the handset. In the final years the plastic-covered curly cord was introduced. The handset itself was usually marked with the manufacturer's code and/or the number 164 in a recessed oval under the handgrip. As the phone was produced for the BPO by a number of companies, a corresponding range of dials was fitted over the years.

The ITI Telephones

The moulds had to be reconditioned before use in India. This is usually achieved by sandblasting and repolishing the moulds, but some detail is lost and the Indian phones look a little worn compared to the British versions. The later Indian telephones may lack the sharp edges of British phones, and they have a duller finish than the British ones. They were produced in the older bakelite, probably with wood flour or talc as a filler. This gives a slightly less glossy finish and weathers to a dull surface. Apart from this there are major external differences. ITI did away with the note tray, so a blanking plate was fitted across the tray opening. The handset, which on the British ones is marked 164 or carries the manufacturers logo in a recessed panel, now had an oval panel with ITI in stylized script embossed into it. The handset cord was generally the plastic curly cord, not the cloth-covered cord of most British phones, although for some years cloth cords were used. The Indian phones were generally fitted with what looks like an ATE 24C dial, but the company made its own dials using ATE equipment to the same specs as the 24C. They will usually carry the ITI brand on the back. Internally the Indian phones are quite different from their British predecessors. Without the need to put in rails for the tray to slide on, a flat baseplate was used. Components were mounted directly to this base rather than built onto a chassis as in the British models. The capacitor is a large rounded one rather than the British flat one. Grommets are fitted to the case where the cords enter. The baseplate will usually be clearly marked "Indian Telephone Industries, Bangalore" with other production markings. At some time during its production run, the phone was fitted with a new Indian-produced receiver capsule. This required that the receiver housing be made slightly smaller on the inside. The colors produced were peach, blue, pink, light green, ivory, white and black. The ITI phones overall were a well-made, well finished design, with minor changes from their British predecessor to allow for India's needs and preferences. The dial on the red phone has been stripped back to brass. This is a later modification.

Left: ITI baseplate. (Courtesy Bob Freshwater) Right: ITI logo embossed into the handset in a shield-shaped figure and oval indent.

Left: ITI internals - well made and professionally finished.

The Later Copies The producer of these phones is unknown. They appear to have been made after ITI stopped production of the 332, although some appear to have been reconditioned from genuine originals. The well-worn moulds were again renovated, very roughly. The edges are very soft and rounded, and parts of the case may show file marks where the ridges from the worn mould joints have been removed. An oily film may be present on the surfaces, possibly a mould release compound. Although they seem to have been produced in the full ITI range of colors, the colors are not very accurate. The red is brighter and more garish, the Ivory is nearly white, and the other colors appear to have fainter colors resulting from less pigment being used. On the reconditioned ones, the ear and mouthpiece caps are very poorly fitted and often of a brighter color than the rest of the phone. They appear to be made of a later plastic, not bakelite. The ear cap does not screw all the way onto the handset because a deeper receiver capsule has been fitted.

The rubber feet on the baseplate are square and stuck on, not mounted with screws as on the original ITI and British phones. The baseplate itself may show signs of corrosion as it is very cheaply plated. Internally, a cheap ringer is fitted with deeper, roughly stamped bells. Wiring is generally poor quality, and failures have been reported as being common. The handset has the ITI logo on a raised oval instead of recessed.

Left: Reproduction handset with raised oval for logo Right: Copy. Note the poorly fitting and too-bright receiver cap, brass dial, cheap plastic curly cord, and generally softer moulding on the case egdes.

Some collectors have attempted to update these copies by fitting more accurate components, but this requires a level of skill and machining tools that the average collector will find hard to obtain. As an example the receiver must be replaced, and the handset moulding is a fraction smaller than the genuine one. It must be machined out and some of the thread removed so the correct capsule can be fitted. The phone has the wrong number of terminals and will require some adjustment of the electrical wiring. Unfortunately some phones have also been "done up" cosmetically to more closely resemble the real thing in the hope of a better price on Internet auctions. These phones have given the whole range a bad name. This is unfortunate, as the genuine ITI phones deserve the attention of collectors as a local version of a proven and widely used design.

References Freshwater R "Collectors Information - 300 Type Phones" at http://www.britishtelephones.com/collect.htm

| |||||

This was

a carefully designed and well made phone, intended to stay in production and

in service for a long time. It was originally made in bakelite, but just before

the Second World War the material was changed to polymethylmethacrylate. The

new polymer was glossier, slightly translucent, and less subject to the crazing

that bakelite showed after a while. It also allowed the phone to be produced

in green, red and ivory.

This was

a carefully designed and well made phone, intended to stay in production and

in service for a long time. It was originally made in bakelite, but just before

the Second World War the material was changed to polymethylmethacrylate. The

new polymer was glossier, slightly translucent, and less subject to the crazing

that bakelite showed after a while. It also allowed the phone to be produced

in green, red and ivory.

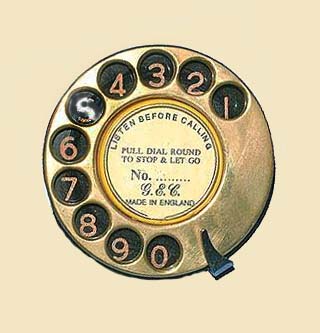

The dials

used were often marked GEC and the fingerplate is brass, not stainless steel.

Reports from repairers suggest that the brass dial may be counterfeit, as it

seems to be quite unreliable. It is possibly a much older dial polished back

to brass to make it more appealing to buyers. Reports suggest that most of them

have only one centre screw, as against the two screws on the genuine dials (see

photos above).

The dials

used were often marked GEC and the fingerplate is brass, not stainless steel.

Reports from repairers suggest that the brass dial may be counterfeit, as it

seems to be quite unreliable. It is possibly a much older dial polished back

to brass to make it more appealing to buyers. Reports suggest that most of them

have only one centre screw, as against the two screws on the genuine dials (see

photos above).